Participating projects involved integrated circuit design, photoresist as a key material of integrated circuit packaging, new energy, intelligent manufacturing, great health and other fields

On November 15-19, the 24thChina High-Tech Fair (CHTF)was held in Shenzhen. SZPT selected 18 teacher projects, 5 student maker projects and 6 technologicalresearch platforms to participate in the exhibition. The projects involvedintegrated circuit design, photoresist as a key material of integrated circuit packaging, new energy, intelligent manufacturing, great health and other fields, fully demonstrating the college’s ability to keep up with the forefront of industrial development, serve the innovation of enterprises at source, and promote the market transformation of scientific research results, as well as the latest achievements of innovation and entrepreneurship education at SZPT.

In recent years, SZPT has adhered to the application-oriented scientific research, actively carried out transformation services for industry-university-research technological achievements with enterprises and third-party institutions, leveraged the “China’s No. 1 Technology Exhibition” to transform technological achievements, and built a professional and market-oriented transformation and trading mode for technological achievements that combines online and offline.

Keep up with industry needs and solve key technical challenges

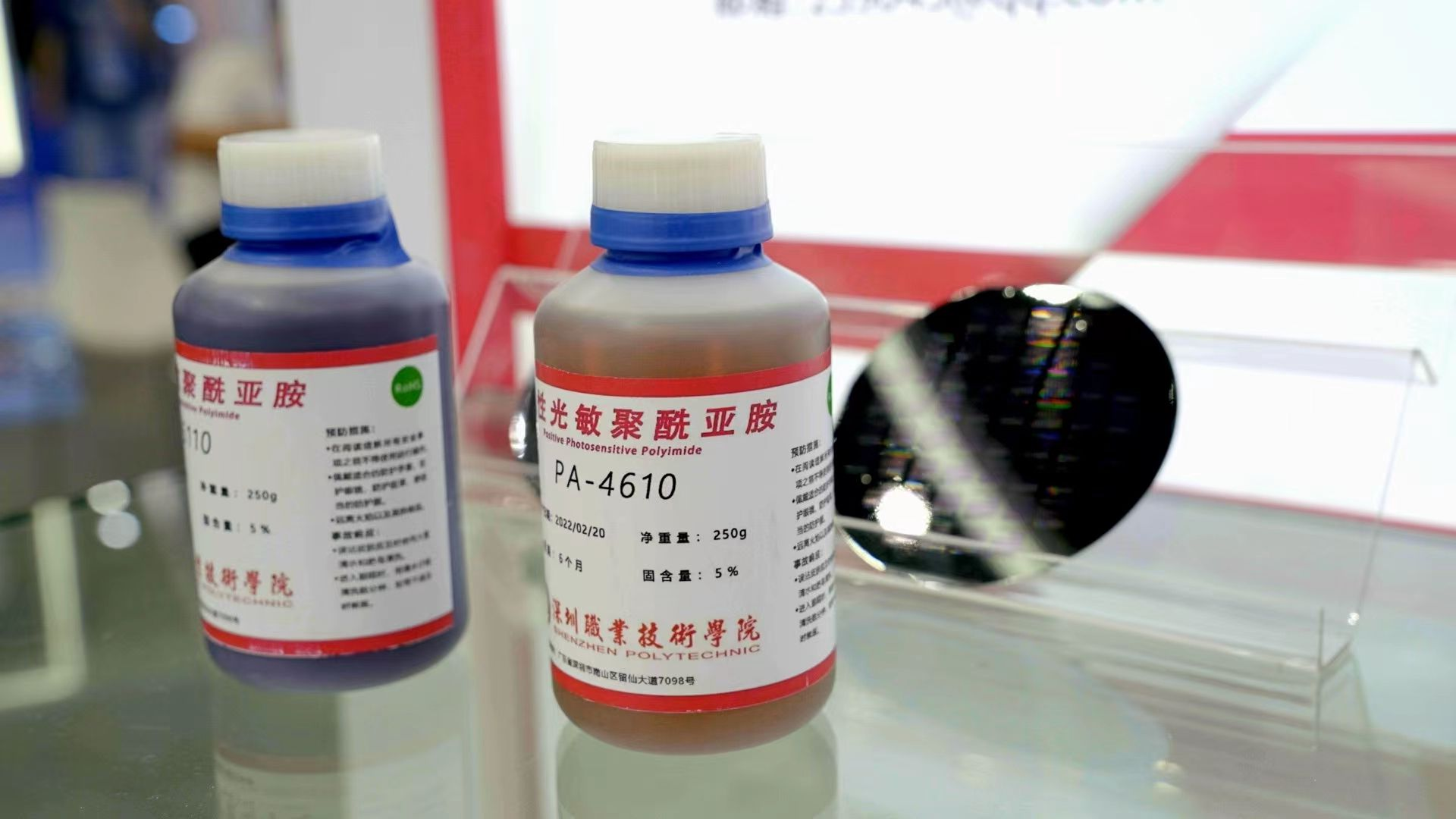

Walking into SZPT’s exhibition area, two plastic bottles filled with liquid caught everyone’s eyes. Don’t underestimate them, because they contain the “photoresist as a key material of advanced packaging for semiconductor chips”.

The Institute of Key Materials for Integrated Circuits of SZPT exhibited the photoresist as a key material of advanced packaging for semiconductor chips at CHTF

“The semiconductor chip manufacturing process is the stacking of lithography layer upon layer. You can think of it as building a house. You need to put the bricks on top of each other based on the design. Each lithography is equivalent to building a higher layer of bricks, until the house is built.” According to Teng Chao, the project leader and professor from the Institute of Key Materials for Integrated Circuits of SZPT, lithography works in a similar way to taking a film photograph: the lithography machine is the lens of the camera, and the photoresist is the negative; through the process of exposure and development, the design graphics can be displayed on the negative. The chip is made by repeating the process of taking photos over and over again, and superimposing many negatives on top of each other. “The photoresist for advanced packaging we make is to form the required graphics on the surface of the chip by taking photos for many times, so as to realize the communication between the internal signal of the chip and the outside world.” As one of the key materials for advanced packaging of semiconductor chips, this material has been monopolized by Japanese and American companies. For the 4100 type products monopolized by relevant companies in the industry, SZPT’s electronic materials R&D team has been active in scientific research. At present, the research and development of domestic substitute products has been completed, with comprehensive performance equal to that of foreign similar products, expected to enter the mass production stage in the next year.

High-level institutes of applied technology boost industrial upgrading

This year, six technological research platforms at SZPT were unveiled successively, including Hoffmann Institute of Advanced Materials, Institute of Intelligent Science and Engineering, Institute of Intelligent Manufacturing Technology, Institute of Marine Biomedicine, Institute of Artificial Intelligence Application Technology of Guangdong-Hong Kong-Macao Greater Bay Area, and Institute of New Energy Vehicle Technology.

The head of the scientific research department at SZPT said, in recent years, the college has continuously deepened the reform of scientific research system, vigorously strengthened the cooperation with functional departments of the government and various enterprises, actively sought a position in the technological and industrial chain, and set up a number of high-level applied technology innovation research institutes and public technical service platforms. At present, the college has built 10 high-level applied technology research institutes, and established high-level public technical service platforms such as Shenzhen automotive electronic product testing and identification, digital creativity, biochemical analysis, software quality and system safety testing, in order to provide testing, research and development and other public welfare services for micro, small and medium-sized enterprises.

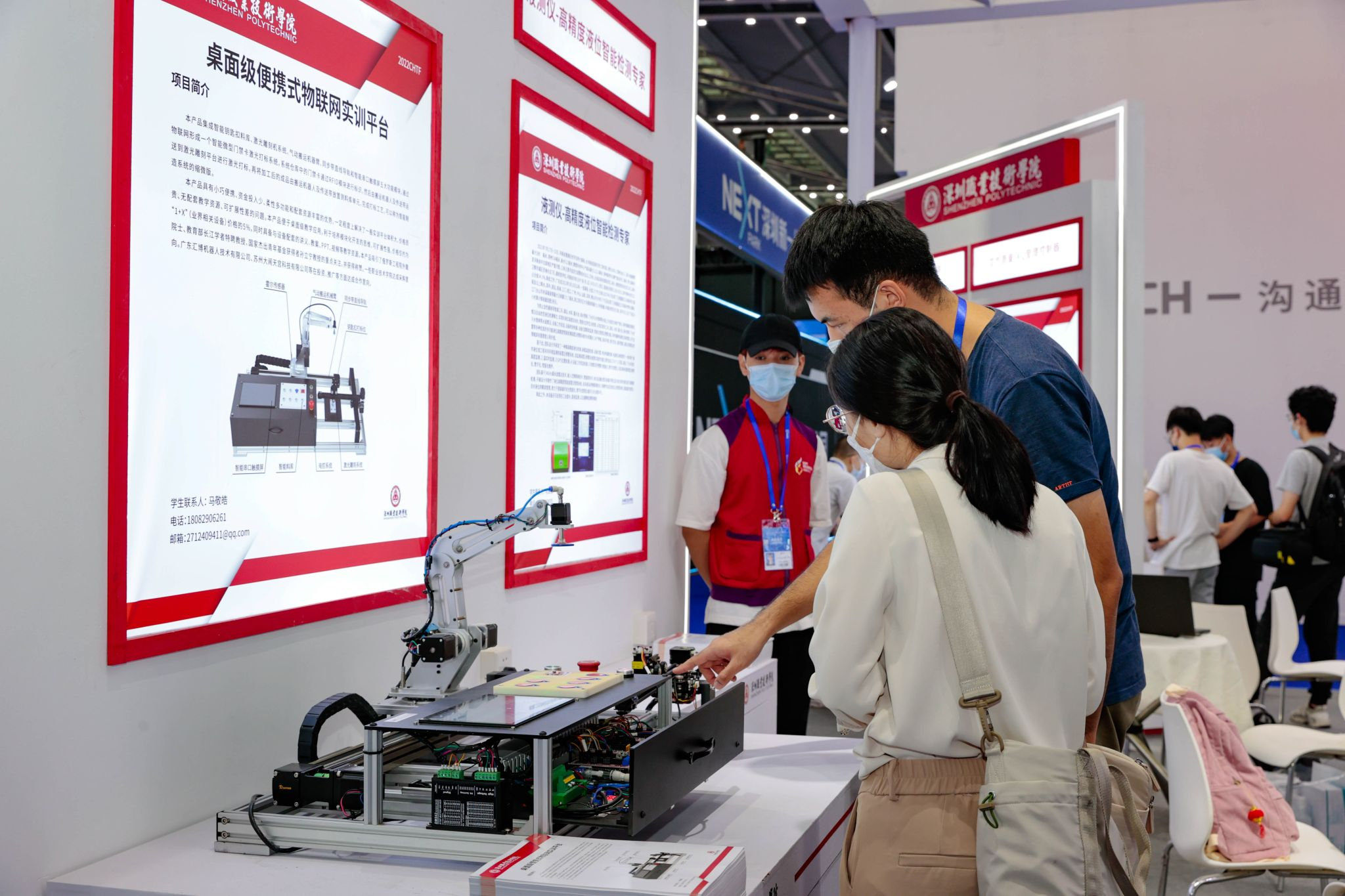

The audience checked the college’s scientific research project in detail

After 4 years of development, the high-level institutes of applied technology have produced quite a lot of scientific research achievements, including the photoresist as a key material of advanced packaging for semiconductor chips, LCD core material, and key material in the electronic acoustic field, as three scientific research achievements exhibited by the Institute of Key Materials for Integrated Circuits at CHTF. The team from the Institute of Key Materials for Integrated Circuits has made important technological breakthroughs in the research and development of key materials in the fields of advanced packaging for semiconductor chips, advanced display, and new-generation communication technology. Several materials have entered the mass production stage, making positive contributions to industrial upgrading.

Maker projects to cultivate innovative talents

The “SZPT Maker” element is also another highlight in the college’s exhibition area. The student maker projects exhibited at CHTF are focused on electronic information products. All the five student maker products possess independent intellectual property rights, which closely follow the market demand and have broad market prospects.

The team member was displaying the UAV power battery health condition diagnosis system on site

The project demand of “UAV power battery health condition diagnosis system” comes from the power grid line inspection department. In practical work, UAV has been massively used in the inspection of power grid lines. However, battery life has been a major constraint on the development of the UAV industry. To be able to simultaneously detect and manage the health condition of hundreds of UAV power batteries, the SZPT student maker team devoted themselves to the research and development of diagnosing battery health condition based on active excitation and feature model, and developed a lightweight and portable device of automatic detection, one machine for multi-detection, and intelligent algorithm, which can meet the needs of diagnosing the health condition of commonly used UAV power batteries. The prototype product has been provided to power grid companies for pilot application and is well received.

With the continuous improvement of living standard, people pay increasing attention to their health and diet. How to eat healthier? How to exercise more effectively? Is there an app to solve the pain points and needs of fitness people at the same time? “We found that similar products on the market did not combine diet and exercise data closely enough to obtain comprehensive data information of users’ body parameters, and did not do well in food recognition and video action analysis, resulting in poor user experience. Based on the above problems, we set about product innovation.” When talking about this work, Liu Jiaqi and Li Guiye, two students from the School of Mechanical and Electrical Engineering, opened their mouth: as students not majoring in the field, they needed to spend more time and energy to learn and explore relevant professional knowledge; in order to make the data more accurate, they tested and adjusted the equipment parameters many times, making the results approximate to the most realistic data…Hard work pays off. Eventually, they developed a “Personal Coach” that can automatically identify food items and calories, and provide remote teaching and exercise instruction via the camera, so as to better track the user’s overall physical condition and make it possible for everyone to have a “Personal Coach” at home.

According to the introduction, all the maker projects in this exhibition are selected from the college’s “Maker Project Optimization and Upgrading” program. The program aims to improve the quality of projects, promote the industrialization of projects, and create a new model of the innovation-entrepreneurship ecological chain. All the shortlisted maker projects have completed preliminary product prototypes and possess certain innovation, technical barriers and market potential. In the process of project optimization and upgrading, the college will help students to set up an interdisciplinary R&D team of school-enterprise cooperation, constantly enrich their crossover knowledge and skills, improve their innovation ability, and strive to cultivate innovative talents with crossover thinking.

(Wu Yisu, Department of Publicity, Text by Huang Shuyan, Convergence Media Center, Image by Xie Jiakang and Zhang Weichuang)

School Motto:

School Motto:

Search

Search

School Motto:

School Motto:

Search

Search